The market is tough and so is the competition. Every company wants to keep up in this race and are always trying to outsmart each other. For this, the industries concentrate on maintaining their reputation in the market as it will reflect in their progress charts. Development and the reputation of any industry depends upon the quality of the products or services it penetrates in the market. To keep up to the mark, the manufacturers need a proper application of quality management to ensure optimum results.

|

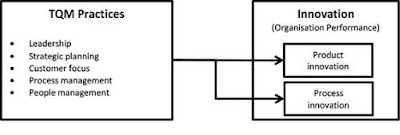

Source=Pubs.sciepub.com

|

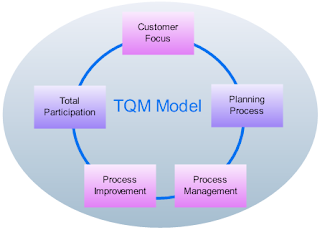

For this, industries have come up with TQM (Total Quality Management). TQM has varied definitions across the globe. It is a way of thinking and can be defined as a management tool, philosophy and set of principles which guide each and every member of the organization to work for meeting customer satisfaction.

The key aspects which make TQM so important for any organizations are,

● Continuous improvement

● Reduce waste

● Doing it right in the very first attempt

● Take quantitative measures to analyse deviations from quality.

As for continuous production in the manufacturing industry, TQM has become more and more popular for several reasons, which are as follows,

1. Competition in the Market

Companies who adopt TQM, not only produce quality products, but also are able to enhance their reputation for adopting the same.

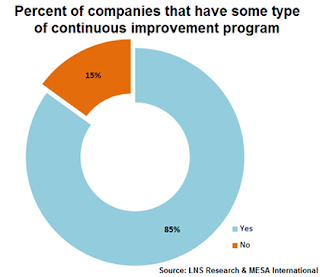

Since its introduction, TQM in the past few years has become an important part in the manufacturing industry. It’s moved on from being optional to a mandatory tool for the industries. It was obvious that a company adopting TQM would have an edge over those who don’t; this made every player in the market to adopt it.

TQM ensures superior quality products and services which can be evaluated in terms of performance. Companies can get an appropriate estimate about their quality value. Companies which put customer satisfaction as their top priority, vastly profit from TQM.

2. For the consumers

The set of guidelines that come along this package does not only ensure quality, but it also helps to maintain the existing customer and also to add new ones in the tab. It is estimated that the cost of maintaining the existing customers is half than that of making new ones. Thus, the main priority of TQM is to maintain this set of existing customers.

For example, assume that you buy a Sony laptop. As the brand name of Sony is already well known, you wouldn’t be questioning its quality, but if it had any defects… what are the chances that you’d buy something of Sony again or would recommend it to someone? Most probably none, unless you are a Sony fan!

TQM helps to eliminate the above scenario. It wouldn’t be possible that all the glitches would be eliminated, but with the help of ‘Sigma Six’ tool, the chances of these defects come down to one in a million!

|

Source=Scielo.org

|

It is understandable that the companies do provide after purchase service but as the saying goes, “The first impression is the last impression!”

3. Boosts Revenue

Apart from the customer satisfaction, TQM plays a vital role in increasing revenue by minimizing the input and maximizing output. It ensures high productivity levels of an organization. This is due to the proper management of inventory control and reduction in waste. This enables the employees and suppliers work hand in hand and incorporate ‘Just in Time’ philosophy. Here, SolutionBuggy does an excellent job to collaborate these suppliers and manufacturers by fulfilling their needs of supplies and consulting.

TQM facilitates the cash inflow of an organization with these methods. Money being the priority for a business makes every source of it important. All this being done in appropriate amount of time is what brings TQM into perspective.

Consider if the batch production is being delayed due to some reasons, the whole cash inflow will be delayed due to which the payments of the suppliers and employees can be at a halt. This then becomes a terrifying situation for any organization. No one would like their payment being late… would they?

The main stress of application of TQM in the manufacturing industry is to see that the workflow is smooth and uninterrupted, which makes it so significant. It may be opined that TQM has become an extremely important process in the manufacturing industry today

Register at SolutionBuggy to find TQM consultant / experts in quick time and get your projects done.

SolutionBuggy is an exclusive and dedicated platform for the Manufacturing Sector in India. It seamlessly bridges the gap between the industrial sector and professionals for on-demand consultation and services including projects. It connects SMEs and Large Scaled Industries with Industrial Consultants/ Experts and Industrial Product Suppliers over the internet for collaboration and success.

It is an integrated platform wherein industries can share their issues/ problems and post requirements; consultants/ experts can showcase their capabilities and offer services and solutions and suppliers can list their products to match the industry requirements.

Share

ConversionConversion EmoticonEmoticon