3D printing creation is still in its

early stages; however, it is as of now

inescapable. Also, on the off chance that you look carefully, you will discover

various signs that this memorable move is as of now well in progress.

|

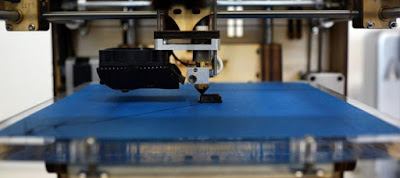

| Image source: Ref= extremetech.com |

From retail products to medicinal embeds and even

sustenance, 3D printing innovation guarantees to change the way we

consider ordinary things. It's hard to anticipate what effect it will have on assembling in any case, whatever the exact

impacts, they are probably going to be profound and lasting.

3D printing innovation has been around in

the mechanical part for quite a while, yet the innovation accumulated standard

consideration when the specialist/creator 3D printing market took off. That was

controlled by fused deposition modelling (FDM) innovation, which utilizes a warmed spout to print material in

layers, developing a protest after some time. The detail on the question is

ordinarily flawed in light of the trouble of putting layers unequivocally on

top of each other.

Otherwise called "Additive manufacturing", 3D

printing alludes to procedures where a question is assembled by layering

materials under modified orders. The object could be of any shape and are

delivered from the advanced model

information or other electronic information sources, for example, an Additive

Manufacturing File.

Mid-3D Printing machines were utilized

exclusively to make Rapid Prototyping (RP) models utilized amid item advancement.

As the innovation has developed, so the

scope of materials accessible to us has expanded, and with this has come

upgrades in mechanical properties and life span. We can now create parts in

metals, for example, titanium or gold, polymers, for example, ABS, Nylon and

polycarbonate or earthenware production, for example, aluminium or zirconium.

Here's the manner by which with all the

business applications, It could upset outline and assembling:

1. With 3D printing, what might have at

first been a progression of phases of creation could be chopped down to an

originator toward one side and the printer or "maker" at the other.

The centre players would in all likelihood is providers of crude materials or

"ink".

Such decreases in the assembling procedure could

influence both local and global creation systems, perhaps bringing about lessened

capital prerequisites, warehousing and different coordinations and transportation needs. These

adjustment underway frameworks could possibly change the general thought of

countries' monetary security.

2. The uniqueness of 3D printing lies in

the way that it decreases multifaceted nature. Parts and segments get together

strides and expenses can all be altogether decreased. The pioneer of the

mechanical production system itself, the Ford Motor Company now utilizes 3D printing to create and gather models.

3. When introductory setup and tooling

costs have been finished, the incremental cost to create parts utilizing traditional assembling procedures is

moderately low. For a few things, for example, a straightforward infusion

shaped plastic part, the cost per part with 3D printing might be 50 to 100

times more than regular assembling strategies at high volumes. In any case, the

cost to create one-off models, exceedingly tweaked items, or low-volume parts

with 3D printers is significantly more prudent in light of the fact that in

advance tooling costs don't exist.

4. Fabricating organizations making another item regularly additionally make a

multi-year supply of extra parts, delivering expansive amounts that are relied

upon to take care of the demand for a

long time or more. In any case, holding a stock

is exceptionally costly. Costs incorporate the cash-flow to deliver the stock,

shrinkage (where parts are essentially lost or stolen), out of date quality,

warehousing, protection, following and dissemination.

5. 3D printing not just upsets

the underlying phases of a generation

where years of stock is made; it generally changes how organizations see the finish of an item's life. Today, a

ten-year-old cooler that works fine mechanically,

however, is missing two racks or

an entryway seal would probably be rejected. Following a time of

administration, all the extra parts created for it are exhausted. The maker

will consider the item "dead," and will at no time in the future

administration it.

3D printing may well require change past

the assembling segment. It will straightforwardly influence urban arranging and

land utilization strategy; ocean and air

terminal improvement for payload; and maybe, more significantly, employment

creation for the masses in creating nations as a pathway to upward portability.

3D printing is still too ease back and

costly to supplant most ordinary assembling applications. Be that as it may, as

gear and material costs keep on dropping, as throughput increments, and as most

extreme form sizes grow throughout the following decade, 3D printing will

extend drastically. Furthermore, it will upset for all intents and purposes

each part of assembling, from introductory plan to shop-floor setup and from

assembling and get together to store network, coordination’s, and circulation.

|

| Source: theweek.com |

3D printing won't swap conventional

assembling for applications where institutionalised

parts should be fabricated in high volumes

and at the most minimal conceivable cost—in any event,

no time soon. In any case, makers need to find where 3D printing can be utilized to make new outlines that are

prevalent somehow, for example, when uniting parts numbers or while making a mind-boggling part that must be delivered utilizing added substance fabricating

strategies.

All these potential changes incite the

key question – do we have to re-align our monetary yearnings in light of such compelling innovation?

Register at SolutionBuggy to find 3D printing consultant / experts in quick time and get your projects done.

SolutionBuggy is an exclusive and dedicated platform for the Manufacturing Sector in India. It seamlessly bridges the gap between the industrial sector and professionals for on-demand consultation and services including projects. It connects SMEs and Large Scaled Industries with Industrial Consultants/ Experts and Industrial Product Suppliers over the internet for collaboration and success.

It is an integrated platform wherein industries can share their issues/ problems and post requirements; consultants/ experts can showcase their capabilities and offer services and solutions and suppliers can list their products to match the industry requirements.

1 comments:

Write commentsGood article. Immense potential particularly for one-off item requirements. Regards

ReplyConversionConversion EmoticonEmoticon